By Eric Paya and Aaron Zigeng Du.

The frontier between fixed and floating foundations

In the ScotWind Leasing Round, around 50% of the Draft Plan Option (DPO) areas are located in “deep water zones”, which have water depths greater than 50 metres. Considering the current rapid pace of offshore wind technology development, many developers are puzzled about where the frontier between fixed and floating foundations in will be the next decade.

Our previously published article Floating offshore wind is here to stay, stated that

for water depths greater than 60 meters, fixed-bottom offshore wind foundations become uneconomic, even though a recent study suggests this frontier might be 90 m. Others believe that the transition between fixed to floating foundations occurs in a zone between 40 to 60 m.

In addition, a poll from our recent webinar, How deep can the monopile go? showed that 60% of 99 participants believed the monopile will extend into 50-70-meter water depths.

In this article, we review various aspects of deep-water monopiles and jackets and compare with floating technology at a more comprehensive level. Some guidance is also provided to developers and clients who are currently facing the dilemma of choosing between a fixed and floating solution.

The upper limit for fixed solutions

The How deep can the monopile go? webinar discussed the key challenges of monopiles in deep waters. There were different opinions on the maximum water depth for monopiles: one expert mentioned 65 metres as the maximum with the current know-how and wind turbine size, going down to 55 metres when wind turbines get bigger to the 15–20 MW range whereas another expert mentioned 70 metres would be achievable. However there are serious challenges to consider such as welding issue for plates thicker than 120 mm, pile installation (i.e. driveability), flange design, etc.

Jackets are technically less challenging than monopiles in deep waters from a design perspective. The main concerns of deep–water jackets are associated with serial production and transport & installation (T&I). The weight and height of the deep-water jacket imply that bigger heavy lift vessels are needed. Although there is no technical strict limitation, the size of jackets will be restricted by the cost of fabrication and Transport & Installation considerations.

The lower limit for floating technology

Under certain conditions, floating wind foundations, such as semi-submersible, barge and tension leg platform, could be installed in water depths as low as 30 meters. However, the current cost of floating foundations is 2-3 times that of fixed foundations, so it is not economically feasible for shallow water depths where fixed foundations can be installed. Therefore, the lower bound of water depth for floating wind is driven mainly by the overall LCOE.

The article Floating Offshore Wind is here to stay has discussed the advantages and potentials of floating wind in cost reduction in the next decade.

What determines the frontier between fixed and floating foundations?

Based on today’s technology and industry experience, we could say that this frontier is somewhere between 60 to 80 metres.

The actual depth for this frontier cannot be the same for all offshore wind farms, and must be considered on case-by-case basis. Developers who seek to find the answer should particularly focus on these three main aspects:

- Soil and metocean conditions

- Future wind turbines

- Local fabrication existence and capabilities

These are not the only issues to look at, but Empire Engineering consider these are the key aspects for the decision-making process between fixed and floating foundations.

Soil and metocean conditions

The geotechnical and the metocean conditions really could drive the choice.

Fixed foundations are significantly influenced by geotechnical conditions. For example, soils too soft make the size of the fixed foundation piles unrealistic, and monopiles cannot be drilled into hard rocks.

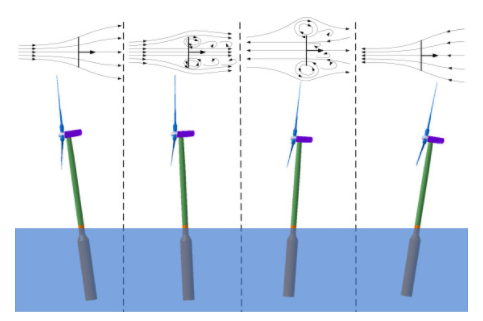

Floating foundations are mainly affected by metocean conditions (waves and current), which can simply rule out the floating wind solution in certain areas. For example, significant high waves can induce high dynamic response of the floater that may exceed the limit of motion, acceleration and heel angle of the turbine. One particular aspect is that high pitch motions can induce unacceptable loads on one side, and loss of efficiency on the other side. In addition, strong currents could lead to floater offset, which, together with dynamic motions, can make the dynamic cable design impossible to work.

Typical WTG pitch motions on floating foundation

Wind Turbine

The size of the wind turbine generator (WTG) is an important factor for the foundation selection and can push towards one solution rather than another. Both fixed and floating offshore wind foundations need to adapt the next generation 15MW to 20MW WTGs, which will be significantly higher and heavier than the current WTGs in operation.

Obviously, the experience of the wind turbine OEM in the floating arena is also important. Using a wind turbine supplier which has no experience in floating technology is a high risk for the project, and lenders/banks potentially involved in the financing scheme may not find this choice a good option.

Fabrication issues and Local contents

One of the main criteria to choose one technology versus another is clearly the requirements from the country with regards to local contents. And it goes together with the local fabrication yard existence and capacities.

To fabricate one hundred monopiles and jackets is a challenge, but it has been done. The fabricators in the Northern Europe / North Sea area can do it and they have learnt from existing projects. However, it has never been done for floaters and this may be the real bottleneck for some development projects. As the whole floating industry is gearing up for industrialization and serial fabrication this can be overcome within the next 5 to 10 years so we have to see how this topic evolves. Potentially using fabrication facilities in the Far East for European projects is an option given that the overall cost including transportation is still competitive.

In countries and markets where none of the fixed and floating fabrication facilities currently exist, where everything needs to be built from scratch, then floating technology may have an advantage.

Empire Engineering are offshore wind foundations specialists. We’re experienced at facilitating a rapid resolution of issues, managing risk and maximising the benefits to your project. If you would like assistance with your offshore wind project on schedule, please get in touch.

Aaron Zigeng Du is a Head of London office at Empire Engineering.

#empireenegineering #offshorewind #risk #offshorewindfoundations

Talk with a specialist

We've been a part of some of the worlds most exciting and

complicated projects in offshore wind.

If you need more eyes, brains and hands, we're ready to help.