Mathias Viallon is a Senior Transport and Installation Engineer at Empire Engineering. Here, Mathias shares his insight into the impact of weather conditions on offshore wind projects.

Who doesn’t like a bit of weather chit-chat?

The weather is a timeless small-talk favourite at boring parties and with neighbours, however in the maritime and offshore world, it’s an especially important topic.

Weather sets offshore work apart from onshore activities. It affects sea transport, key heavy-lift operations, and subsea tasks. Practically all of these are limited by weather.

Safety and risk

Typically, the more operations are pushed to the limits, the riskier they become.

Rather than setting a hard limit, such as design wave height, finding an acceptable risk level to perform the operation is a more gradual assessment.

The approach may involve multiple stages, depending on the weather conditions. Good weather with no special risks might need one approach, while severe conditions require additional mitigation measures.

The safety of the crew is always paramount, but a risk is never zero, and residual risk will always remain.

The best global assessment will always be the viewpoint of the Captain, Superintendent or other site decision-makers of the operation. They must balance the drive to complete the project with the safety of the crew and vessel.

It’s no wonder that in maritime law, the ultimate decision and responsibility of ship and operations lie with the Captain.

“Weather doesn’t look too bad” according to some guy in the office. (Source: Mariner’s Galaxy)

Weather-restricted operations

Weather will play a central role in all design and planning phases of a project.

The key to a successfully safe and efficient outcome is to give weather a central place in the project risks and opportunities, but to avoid making environmental limits either a contractual or too strict an academic topic.

All design stages should work with the Captain’s view in mind, trying to maximise flexibility of the operation and provide support for informed decision-making.

It is equally important to incorporate the feedback of the operational team in the design.

In practice, structural design or operation planning can follow two paths:

1. Weather unrestricted. This is the classical design case for structures, or long marine transport operations. A conservative estimate of maximum conditions is applied to the design verification case. In reality, this is still a risk-based assessment, and extreme weather conditions can exceed the design assumptions, such as rough waves for structures or storms for transport operations. Though design factors are often dictated by guidelines, it’s wise to still consider contingencies and assess the project risk in similar fashion to that below.

2. Weather restricted. This applies to almost all offshore operations and some intermediate design cases for structures (e.g. initial on-bottom stability). The operation can be further classified as:

a. Operations “immediately” abortable at any time (in a short time frame compared to weather forecast timelines), such as personnel standard cargo transfer or rock dumping.

In this case, design limits are established. The operation is stopped whenever assessed unsafe or above limits by the vessel Master or Superintendent. The percentage of weather standby expected can be analysed based on historical weather data, and later as a short-term forecast before the operation.

Aborting the operation can come at a cost, such as when terminating a cable for cable laying operations, or the activity may have an influence on other project tasks. In these cases, it’s especially important to forecast the operation, monitor the weather, and make informed decisions.

b. Operations that need to be completed once started, or necessitate a time for contingency abortion, such as a complex heavy lift or a barge tow.

This type of operation requires an assessment of the weather forecast before starting.

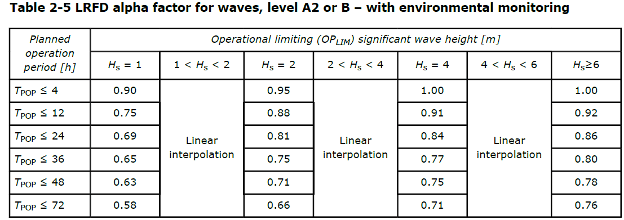

The operation design considers environmental “design conditions,” which act as a limiting value. The DNV guideline for marine operations provides “alpha-factors,” which reduce the “design limit” to an “operational limit” to consider the uncertainty of the weather forecast.

Alpha factors for operational limits (Source: DNV ST-N001)

The alpha factors are dependent on:

The quality of the weather forecast and monitoring

This can range from a single generic weather forecast, to various site-specific forecasts including live environment monitoring and the presence of a meteorologist onboard of the installation vessel. It is relatively easy to assess whether investing in better forecasts is beneficial compared to the vessel and knock-on effect costs. It is often highly beneficial to increase accuracy, as the extra costs are small compared to the benefit. For large installation vessels, a meteorologist on board is advised, and for transport, a route-specific forecasting service can reduce risk and costs.

The design limit (often wave height)

For lower design wave heights, a larger safety factor is applicable, as forecasting for low weather conditions is less accurate. There is a clear benefit to increasing limit conditions.

The length of the weather window (planned operation period in DNV definition)

This consists of the frequency of the weather forecast issue, the design duration of the operation and contingency time, and time to abort the operation. Optimising this critical time is one of the biggest levers that is sometimes unexploited. Apart from the actual operation time, planning for effective contingencies that reduce the necessary time window can bring large benefits.

Weather design criteria

In the design phase, the operation is analysed to define the weather limits. Key considerations are site specific metocean conditions and defining and choosing appropriate limits for the operation.

Site specific metocean conditions

This is analysed to ensure that the chosen environments are realistic. Specific consideration should be given to:

- Waves: height and wave period probability, spectrum shape, directionality, separate swell occurrences

- Wind speeds, directions, gusts

- Current speeds and behaviour (tidal or ocean currents) depth profile

- Seasonality of conditions, variation across site extents, correlation of conditions for example, wind/wave magnitude and directions

- Any other aspect potentially affecting the operation, such as fog, underwater visibility, or temperature

Although computational capabilities are steadily increasing, an analysis will never cover the infinite combination possibilities of environments.

At best, three variables can be considered: most commonly wave height, wave period and heading of the combined environment. Other parameters are fixed (e.g. wind and current speed). Variables rarely accounted for are loading conditions and windage areas. It is important to keep these limitations in mind to understand that the analysis’ discrete case is merely an indication and simplification.

On the other hand, over-simplification is detrimental. Many operating limits, especially for routine operations, are expressed as wave heights alone, which is often not representative of a workable environment. Whenever possible, operations with ships should at least consider wave periods and define wave height/period tables as limiting criteria. It can be more representative to express the criteria as observable parameters, such as vessel roll and heave motions.

Defining and choosing appropriate limits for the operation

Appropriate limits can be:

- Limiting loads in rigging, mooring, hydrodynamic forces, impact forces

- Vessel motions, point motions or separation distance between two vessels

- Maximum accelerations

- Crane pendulum swing motions

- Maximum vessel heel

- Maximum excursions for positioning accuracy

- Dynamic positioning limits

- Limits for specific equipment or routing operations (e.g. personnel transfer)

It is beneficial for the execution phase to clearly define the limiting factors. Many aspects can be monitored (e.g. vessel motions) to support a go-ahead decision, even if the environmental conditions combination is different to the analysis.

A technique developed over the last few years is a motion prediction performed based on a short-term forecast. This covers the gap between theoretical analysis and real conditions. The hydrodynamic analysis (sometimes a simplified model) is run with the weather forecast wave height and period predictions. This is mostly done by a specialist engineer on board and can give valuable insight to the vessel management team and all involved parties leading to increased confidence.

A nice relaxing time for the crew. (Source: Miros)

Weather risk management

Predicting weather downtime using the operational limits is part of the project design loop.

The outcome provides valuable information that will feed into schedule review, campaign planning, decisions to change design or operational sequences to increase workability.

The analysis is generally done with specialist software that uses historical metocean time series, applying the operational limits for each operation and derives the schedule impact at various risk levels.

It is important to consider the interaction of various operations, such as feeder vessels interacting with the installation vessel, for an accurate result. Similarly, other factors such as fabrication delays can have severe repercussions on weather effects.

These activities should be at the centre of the project in a weather risk management plan that guides design and operational decisions in an iterative loop.

It can provide a solid design basis for:

- Assessment of site conditions

- Forecast and site monitoring strategy, including forecast calibration and continuous improvement

- Modelling design brief

- Basis for cost/benefit assessment

- Motion monitoring systems and back-analysis for future improvement

- Schedule forecast and contingency plans

Marine and equipment spread uptime/downtime monitoring, logistic planning - Operational feedback and improvement

This approach can also give all parties, including different Contractors and Marine Warranty Surveyors, early insight and involvement to help to reduce disputes.

Field work

It is important to define how to conduct the operations ahead of starting, and to align the requirements and interfaces.

For the weather forecast service, the following should be considered:

- Sharing site details and past observations, ensuring forecasts are calibrated to site conditions, local features are to be considered, and sub-models are established

- Ensuring the weather forecast service has experience in the region

- Defining the availability of forecasters dedicated to the project

- Defining the time and frequency of the forecast delivery and possibilities to issue ad-hoc specific forecasts when needed

- Defining what will be forecasted: wind wave, swell, period, wind speed (at suitable reference heights as mean, gust, current speed forecast, visibility and fog, storm warnings). Generally, forecasters can produce a short-term hourly forecast and a longer-range outlook

- Defining the format of the deliverable, suited to vessel needs. If live motion prediction is used, forecasted spectrum data in digital form is needed

- Most importantly, the form and content needs to be integrated in vessel routine, and dialogue established between forecasters and vessel management team

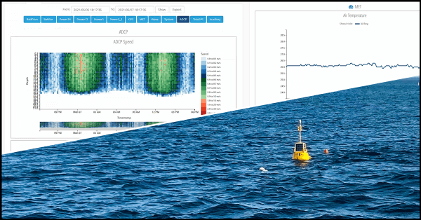

The weather monitoring scheme should address:

- For each measurement, definition of primary and back-up measuring equipment (vessel wave rider buoys, field metocean buoys, anemometers)

- Alignment with all parties which is the preferred source of information to prevail (based on quality of data, closeness to operating site, integration to vessel systems)

- Clarification if data is accessible to all parties in a usable format

A wave rider buoy measuring live wave data (Source: EIVA)

Conclusion

Solid weather prediction, environmental criteria definition and representative scheduling is a central focus area of offshore operations.

Early and thorough integration in the project design and planning process is the key to ensure a successful outcome. Managing interfaces and feedback loops while aligning all stakeholders is a must.

Relying on generic allowances rather than project-focused studies and improvement iterations, delaying the assessment of implications, or solely relying on contractual pressure to meet set weather windows can lead to disaster, project delays, and safety risks.

As projects push into ever more challenging sites, the need for quality assessments, engineering and use of available technologies is even more important.

Reach out to Mathias on LinkedIn or read more about Empire Engineering’s offshore wind expertise.

Empire specialists can effectively and efficiently assist with your offshore wind project. To find out more, please get in touch with the team at Empire Engineering.