Our Engineer Benjamin Trouillard takes us on a guided tour of an offshore HVAC substation.

I’ve had the privilege of working on various offshore structures throughout my career and here, I invite you to join me on a virtual tour of one of the most important components of offshore wind farms: The Offshore Electrical Substation.

These massive structures are often hidden from public view but are crucial to our renewable energy infrastructure. As we delve into the intricacies of these facilities, we’ll uncover some of the systems that make offshore wind energy possible.

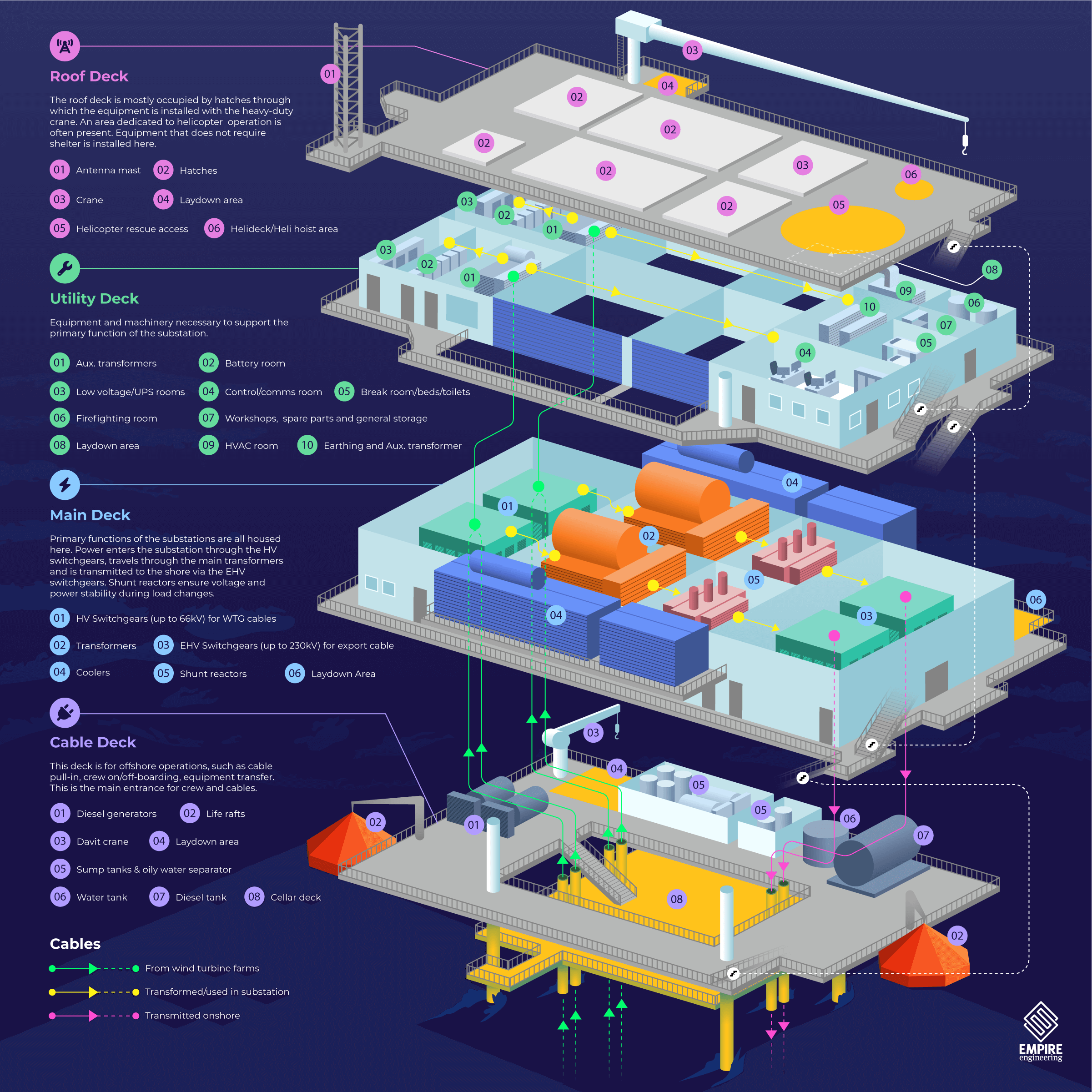

In this article, we’ll explore a representative layout of an offshore substation, from its top deck down to its cable storage level. We’ll uncover the essential functions of each level and gain insight into how these structures serve as the heart of offshore wind energy production. The journey through each deck will reveal not only the technical features but also the ingenuity required to operate these facilities in harsh marine environments.

This overview provides insight into the intricate systems involved in offshore substations, a key component of renewable energy infrastructure. Whether you work in the industry or simply have an interest, we hope this helps demonstrate the important role these facilities play.

Representative diagram of an Offshore Substation – Layouts can vary

What is a HVAC substation?

The offshore HVAC (High Voltage Alternating Current) substation plays a crucial role in the transmission of power generated by offshore wind farms. It acts as the central hub where the electrical output from the wind turbines is processed and conditioned for efficient long-distance transmission. These substations are designed to withstand the harsh conditions of the open sea while performing their critical function. They represent a significant investment in both financial and technological terms, but are essential for making offshore wind energy economically viable and efficient.

Let’s take a guided look through each of the levels of the substation and some of their key features. Each component plays a vital role in the overall function of the substation and the design of these structures is a careful balance of functionality, safety, and efficiency, with redundancies built in to ensure continuous operation even in challenging conditions.

Roof Deck

The roof deck is mostly occupied by hatches through which equipment is installed by the use of the heavy-duty cranes. An area dedicated to helicopter operation is often located here. Equipment that does not require shelter is installed here, including water tanks, diesel tanks and diesel generators. This exposed level must be designed to withstand extreme weather conditions, from high winds to corrosive salt spray. Safety features such as guard rails and non-slip surfaces are crucial, as maintenance crews may need to access this area during operations.

Utility Deck

On this deck, we find equipment, facilities and machinery necessary to support the primary function of the substation, including the auxiliary transformers (the power source for the auxiliary electrical system), auxiliary electrical system (which sustains the auxiliary functions), communications room (for the control and communications within the substation), workshop (for small manual work onboard), UPS (uninterruptible power supply) and battery rooms (to avoid any shutdown). This level serves as the nerve centre for the substation’s support systems, ensuring that all critical operations can continue even in the event of main power disruptions. The layout of this deck is carefully planned to optimise available space while allowing for easy access for maintenance and repairs.

Main Deck

The primary functions of the substation are all housed here. Power enters the substation through the High Voltage (HV) switchgears, travels through the main transformers and is transmitted to the shore via the Extra High Voltage (EHV) switchgears. Shunt reactors (located on this deck) ensure voltage and power stability during load changes. This deck is the heart of the substation, where the main power conversion and transmission processes take place. The equipment here is designed to handle enormous amounts of electrical energy, with robust safety systems in place to protect both the equipment and the personnel who maintain it.

Cable Deck

Finally, this deck is for offshore operations, such as cable pull-in, crew on/off-boarding, and equipment transfer. This area serves as the substation’s primary entry point for both crew members and cables. It also houses the sump tanks along with the oily water separator, for the onboard waste management. The cable deck is designed with flexibility in mind, allowing for various offshore operations to be conducted safely and efficiently. Environmental protection measures are particularly important here, as this is where the substation interfaces directly with the marine environment.

In this exploration of offshore substations, we’ve journeyed through each deck, from the roof to the cable level, unveiling the systems that make up these structures. Each level represents a crucial component in the complex process of harnessing and transmitting offshore wind energy. The interconnectedness of these systems highlights the need for precise engineering and careful planning in every aspect of substation design.

Understanding the function of these substations is key to appreciating the engineering that enables the harnessing of offshore wind energy.

These structures represent the culmination of decades of technological advancement and environmental research. As we continue to advance the energy transition, these offshore substations form a key part of our commitment to a cleaner energy future. They stand as sentinels in our seas, working tirelessly to bring renewable energy to our homes and industries, and paving the way for a more sustainable world.

Reach out to Benjamin on LinkedIn or read more about Empire Engineering’s offshore wind expertise.

Empire specialists can effectively and efficiently assist with your offshore wind project. To find out more, please get in touch with the team at Empire Engineering.