By Aaron Zigeng Du and Eric Paya.

Floating Wind Goes Mainstream

Floating offshore wind (FOW), considered as a niche technology by some, is no longer confined to R&D. It has gradually reached a high ‘technology readiness level’, making it a natural complement to bottom-fixed offshore wind. It is widely thought that for water depths greater than 60 meters, fixed-bottom offshore wind foundations become uneconomic, even though a recent study suggests this frontier might be 90 m. Others believe that the transition between fixed to floating foundations occurs in a zone between 40 to 60 m.

The truth is: nobody really knows where this frontier is! But the facts are: Floating wind is real, is going to grow, and is here to stay.

With around 80% of global offshore wind resources located in water depths of over 60 meters and with a global potential of almost 7,000 GW, it is impossible to ignore this development.

From a technical perspective, FOW turbines can be installed at water depths as low as 30 meters based on some shallow draft floating wind solutions. But economically FOW cannot compete with bottom-fixed offshore wind on shallow water sites at the moment.

The current levelized cost of energy (LCOE) of FOW can be 2 to 3 times as much as that of the bottom-fixed wind (Proskovics, 2019). However, based on the forecast of technology development and continuous cost reduction by WindEurope, the LCOE of FOW could drop to 80-100 Eur/MWh by 2025, and further fall to 40-60 Eur/MWh by 2030, which is very close to the bottom-fixed offshore wind’s LCOE. FOW has significant opportunities of cost reduction in various areas.

Floating Wind Foundations and Proof of Concept

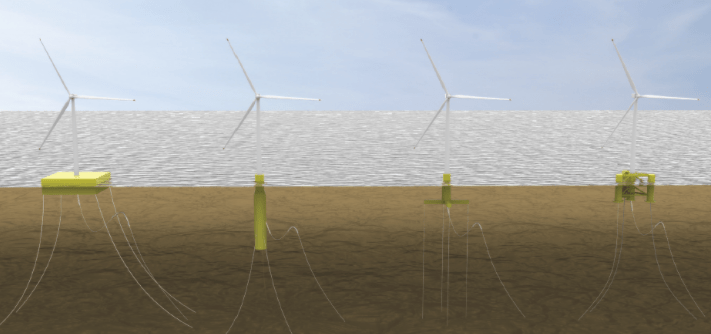

To date, approximately 40 floating wind concepts are under testing, prototype or active development worldwide. Most of them were designed based on the four typical types of floating structures originated from Oil and Gas industry: Semi-Submersible, Barge, Spar, and Tension Leg Platform (TLP), shown in Figure 1. Semi-Submersible became the most popular option in the industry because of its suitability to a wider range of water depths than spar and lower cost of construction and anchoring systems than TLP.

Design Optimisation

The cost of bottom-fixed offshore wind foundations is approximately 30% of the total project cost. In deeper water this further increases because of the larger size of the foundations and higher installation costs. For water depths between 40 to 60 metres, with continuous design optimisation activities, the FOW foundations will potentially be comparable to fixed jacket structures by 2030.

To reduce LCOE, the biggest challenge of design optimisations is to maintain the coupled floater-turbine performance with reduced structural size and weight of steel. Indeed as noted by a recent study the key parameter in the analysis fixed versus floating foundations is the weight. To reach the lightest possible floater design, one of the key challenges is to improve the coupled floater-turbine analysis and integrated design process.

Wind turbine OEMs have been reluctant to test their turbines on new floating structures because of lack of experience and confidence of new floating technologies, and a large backlog of bottom-fixed projects. Wind turbines continue to grow in size and power output, to support future wind turbines of 15-20 MW, and floating structures need to be properly analysed for integrated loads considering the coupled effects from aerodynamics loads on the turbine and hydrodynamics loads on the foundation with the mooring system. This requires close collaborations between floater designers and wind turbine OEMs to provide design optimisation. This collaboration has been presented as one area of improvement recently in various webinars.

With government support, FOW developers need to bring together stakeholders, including wind turbine OEMs, floater designers, technical specialists, and lenders, to accelerate the design optimisation of FOW. Over the past decade the bottom-fixed industry has demonstrated how large optimisations can be achieved through such a collaborative approach.

Assembly and Installation

With regards to the fabrication and assembly process, the contractors and developers must seek improvement in this area in order to bring costs down and prove commercial viability of floating structures.

The fabrication of a large quantity of floating structures must be given particular attention. In the similar way that jackets can be made in parts in various fabrication sites, transported to one final yard and assembled together, floating structures could be built in modules with each module being built in specialized shop. That would allow a ‘serial-like’ fabrication process to be put in place achieving optimum quality.

In terms of final assembly due to the nature of the floating solutions, it has to be done at port. Major investments need to be made in some regions in order to increase the port acreage, the drydock sizes, and float-out draft. And we know that these major investments are pending clear signal from policy makers and governments about the up-coming commercial scale floating wind tenders.

Unlike bottom-fixed offshore wind, where foundations and turbines are installed offshore using expensive heavy lift and jack-up vessels (approx. £200k to £300k/day), FOW foundations and turbines can be assembled at the harbour and towed to the site using low cost tug boats (approx. £30k/day). The weather requirement and time windows for installation of FOW could be also lower than that of bottom-fixed offshore wind. It is reminded that floating structures have been built and installed in the Oil & Gas industry for the past 40 years and the floating wind industry could easily benefit from the existing means, proven procedures, and experienced contractors in order to achieve efficient, safe and cost-effective installation operations. One good example is the successful installation of the Wind Float Atlantic project by Bourbon Subsea who is a well-established marine contractor in the Oil & Gas arena.

Figure 2 from Principle Power

Operation and Maintenance

The cost of Operation and Maintenance (O&M) is around 30% of the total wind farm cost of a bottom-fixed offshore wind farm. The wind farms located further from shore take longer to access, which further increases this O&M cost. Rather than crew transfer vessels, helicopters and large Service Operation Vessels (SOVs) may be required for major O&M activities. FOW may potentially offer a much lower O&M cost than the bottom-fixed offshore wind. For major inspections and repairs, the individual FOW structure can be disconnected from the mooring lines and towed back to the harbour. The O&M activities of FOW carried out in the port is also less influenced by the weather conditions than that of bottom-fixed wind farm.

The current innovations of real time condition monitoring system, incorporating bid data, Internet of Things (IoT), and artificial intelligence (AI) also significantly contributes to O&M cost reduction of FOW assets.

Markets for Floating Offshore wind

There are some specific markets which are more suitable for FOW than bottom-fixed offshore wind. For example:

- Site locations with deep sea water depth close to the coast, such as Norway, Japan and the West coast of the United States;

- Site locations near Oil and gas platforms;

- Islands with high electricity generation costs;

- Shallow water areas with hard rock seabed conditions or strong current which are not suitable for bottom-fixed foundations;

Portugal, UK, France and Japan are leading the way in the FOW development, while Norway, Denmark, US and South Korea are in close pursuit.

The Future for Floating Offshore Wind

With government supports and low-cost financing, continuous design optimisation and improved fabrication process will make FOW a competitive solution for the offshore wind market which is currently dominated by bottom-fixed wind. The knowledge transferred from the supply chain developed in the conventional bottom-fixed offshore wind and oil and gas floating assets are crucial for the FOW development. We believe FOW can significantly reduce its LCoE, achieve economies of scale, and reshape the offshore wind industry in the next decade. To achieve the long-term goal of Paris Climate Action Plan, FOW may well play a significant role in the wind power sector. Perhaps FOW will not just be a competitor of bottom-fixed offshore wind, but it may become one of most attractive options of clean energy.

Empire Engineering are offshore wind foundations specialists. If you would like to find out more please get in touch.

Talk with a specialist

We've been a part of some of the worlds most exciting and

complicated projects in offshore wind.

If you need more eyes, brains and hands, we're ready to help.